The machines that I used to make my product the best it could be is the band saw and the sanding machine. The workplace health and safety that has to be considered when using the band saw is to: always wear safety glasses in the shop, keep machine free of debris, no loose clothing (e.g. pull up long sleeves, no jackets), pin back long hair, make sure guide is on blade to prevent wandering of the cut, blade teeth should be pointing downwards be aware who’s in the machine shop and around your work place, no barefoot footwear (e.g. sandals) and always check with the teacher if unsure. The band saw was used for me to cut my acrylic square for the base of my iPad holder. The sander workplace health and safety issues that are to be taken into consideration is to always wear safety glasses with side shields or safety goggles, keep the work area free of debris, have the dust extracting system turned on and connected to the sander. Because of the dust created when sanding wood, the fire and explosion hazard is considerable, ensure that fire extinguishers are available and that persons working with the equipment know how to operate the extinguishers, make sure that the sanding belt tracks properly and loose fitting clothing should not be worn as well as to tie back long hair. The belt sander was used for me to cut my tube to make the stand for my iPad holder.

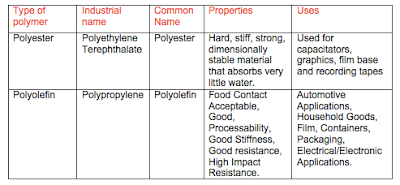

2. The material you are using for your desk tidy is called Polymethylmethacrylate (ACRYLIC). It has specific properties and uses. Choose 2 other common polymers and in table form give their industrial name, common name, properties and uses.

3. Extrusion, injection moulding, compression moulding, vacuum forming and laminating are examples of common manufacturing processes used with polymers (Plastics).

Choose one process and with the use of diagrams and bullet points outline the process. Specifically designed to facilitate the replacement of metal components with polymers, the compression moulding process is a method of moulding in which a preheated polymer is placed into an open, heated mould cavity. The mould is closed with a top plug and pressure is applied to force the material to contact all areas of the mould. Throughout the process heat and pressure are maintained until the polymer has cured.

4. Extension Work - Using processes acquired from your maths lessons, calculate the amount of acrylic sheet that your FINAL desk tidy represents. Show all calculations; answer needs to be in square meters.

Square Base:

A= L x W

A= 200 x 200

A= 40, 000m²

Stand Holders:

A= L x W

A= 0.045 x 0.04

A= 0.000167225472m²

A= 40, 000m² + 0.000167225472m²= 40,000.00016723m²

∴ the amount of square meters used is 40,000.00016723m².

Evaluation

I am very delighted over my desk tidy which is a iPad holder because to be honest I thought there would have been a lot more problems to my design and things that wouldn’t be able to be solved but nothing like that happened! If there were tiny problems I was able to solve them in minutes. My iPad is able to stand up, doesn’t take up to much space and it is stable.

Function

My iPad stands role is to stand an iPad up and being able to use the iPad efficiently whilst it being in the iPad stand. This does what it is designed to do perfectly. There are no problems with my stand and it doesn’t need any mending. If I had to improve something it would be that I spray-painted the entire stand but I couldn’t do this the first time because the spray paint ran out.

Aesthetics

My stand is modern and up to date in the modern would industry. It is shaped very smartly and twenty-first-century. It was the little two things on the bottom to stop the iPad from falling are very smart, as it is not thought out a lot. I also like the tube the only colour on there as it would’ve just been plain but it stands out.

Ergonomics

My iPad stand is very ergonomic. It isn’t too big for a desk tidy and it isn’t all in your face with the colours. There is nothing I would change because it is very ergonomic and easy to work with. It is also very good because you can play on the iPad no matter what because nothing is in the way.

Economics

To make my iPad stand the total cost was $22.80, with:

• Plastic pipe at $4.90 per meter each.

• Acrylic at $17.90 each.

To make the iPad stand it took around 3-4 hours with 4 lessons. If I were to make the iPad stand again I would be quicker and more efficient with making it because I would know what to do and if there were any things I made a mistake with I could fix it easily and quickly. I would estimate the time it would take me to make it again to be 1-2 hours. The selling price I believe you could make a profit out of and be reasonable I would sell it at $18.00. This means I would make a profit of $5.20 but taking away the transport and packaging it would be around $2.30. I think this is good because it I sell a lot of them I would make a good business and stable profit.